This post isn't a "how-to". There are a few of these on the internet that try to show you how to make your own split nuts and some of them illustrate very dangerous methods. If you have the proper equipment (a lathe and a mill) making a few saw screws and split nuts can be fun, but you learn very quickly that the screws offered for sale by most modern saw makers are more than reasonably priced. I don't sell any because mine are patterned off of the old cast style screws with the tapered head. To seat mine properly you need a special countersink, and I don't plan on making more of them.

This is how I make the split nuts using a lathe and a mill.

The brass can be bought from McMaster-Carr in 7/16 dia. For the sake of efficiency I make them two at a time, working off both ends.

First I drill for 8-32 thread.

Tap

In the mill I set up a .040 slitting saw and make a cut .060 deep.

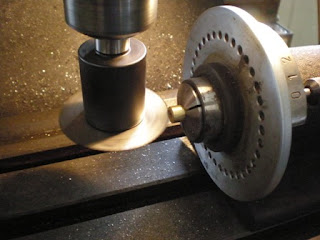

Back to the lathe where I measure back an eighth, plunge in, and back-cut the taper.

Then cut it off. In the picture above you can see I have a take-home container from some restaurant that sits nicely on the lathe bed. This collects the nuts as they get cut off and prevents me from having to dig through those nasty birds nest (probably full of tetanus) that would otherwise steal my finished product and not return it without a fight.

After that it's time for a little clean up with a belt sander and the tap. Done. Easy, if you have the right equipment. If you don't, just buy the screws. A drill press is not a mill is not a mill is not a mill, just as a chunk of railroad rail is not an anvil is not an anvil is not an anvil . . .